Originality

Kuraray Kuraflex will become a specialty nonwoven manufacturer.

We will harness the Kuraray Group's technological capability to open up a new world of nonwovens.

-

Special materials

-

Unique process

-

Combination of

processes

Originality of Kuraray Kuraflex

-

As a member of the Kuraray Group, we can produce special nonwovens using Kuraray's proprietary materials.

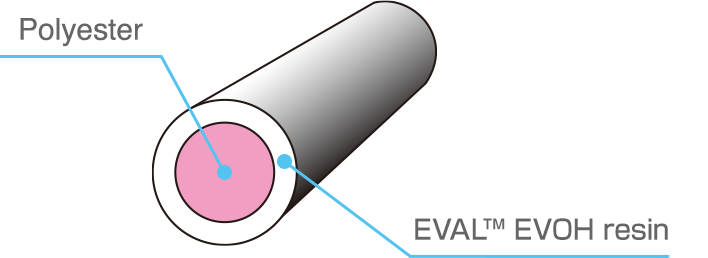

For example, by including SOPHISTA™, which is made from EVAL™ EVOH resin and polyester, in a nonwoven, it is possible to produce a liquid releasing fabric that maintains the features of EVAL™ EVOH resin, that is, superior water or fat solubility.

Cross-section of SOPHISTA™ In addition, it is also possible to produce highly functional nonwovens by using special materials such as SEPTON™ thermoplastic elastomer with excellent stretchability, or Polyarylate resin with its high strength and superior heat resistance.

EVAL and SEPTON are trademarks of Kuraray's special resins.-

- Kuraray's Special resin

-

-

-

- Nonwoven fabric

-

-

-

Unique process

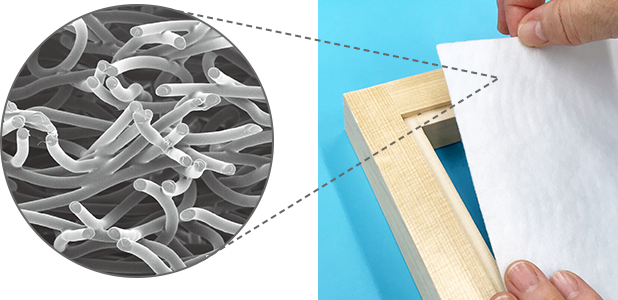

We have four nonwoven processes. Among them, steam jet process is the only process in nonwoven industry.

By combining fibers with Kuraray's proprietary fiber, it is possible to produce self-adhesive bandages that can be cut by hand, without scissors, or shoji paper for Japanese doors that is insulating and durable.

A self-adhesive bandage that can be cut by hand

A sheet for shoji doors, with a 3D net structure -

Combination of processes

It is also possible to combine our four nonwoven processes. Fabrics produced in these ways can have a range of simultaneous functions.

For example, by combining a polypropylene meltblown nonwoven with a cellulose spunlace nonwoven, a moisture absorbing fabric that feels good on the skin is realized.

A moisture absorbing fabric that feels good

on the skin for facial sheet masks