Original fabric (roll)

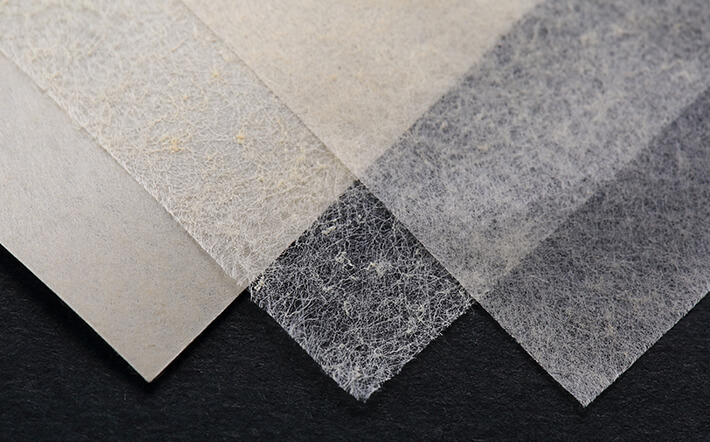

VECRUS™ High strength & heat resistant nonwoven fabric

What is VECRUS™ ?

VECRUS™ is a nonwoven fabric made from liquid crystal polymer (LCP) using Kuraray's unique technology.

It is particularly strong (tensile strength, abrasion resistance, and dimensional stability), and makes products smaller, lighter, longer-lasting, and faster communication.

Composed of ultrafine fibers, it is a low weight and excellent air permeability.

Compared to metal foil and film, it has shape-following properties.

Benefits

properties

For further information or data sheet, please request from CONTACT US bottom.

Application example

Electromagnetic wave shielding

VECRUS™ with metal plating process provides excellent shielding properties, especially in the high-frequency range(>100MHz).

Low weight and high strength of VECRUS™ enable electronic devices to be made smaller and lighter.

Battery Separator

VECRUS™ is a nonwoven fabric made of microfibers that has porous structure and air permeability, so it does not inhibit the transportation of ions to and from the cathode and anode of the battery. Thus, it allows for higher capacity and output of batteries.

Heat resistant sheet

VECRUS™ has a melting point of over 573K(300℃), making it suitable for applications requiring heat resistance.

It is also a non-fluorine material, so it can be used as an alternative to PTFE and other materials to comply with PFAS regulations.

Circuit board material

Since low dielectric properties derived from LCP prevent loss and attenuation of high-speed signals, VECRUS™ contributes to high-speed communication.

Also, low weight and high strength of VECRUS™ enable electronic devices to be made smaller and lighter.

Reinforcement material

Low weight and strength of VECRUS™ satisfy market demands for smaller, lighter and longer the life of products.

Since VECRUS™ absorbs very little water , it exhibits very stable electrical and physical performance even under humid conditions.

Material properties

| Type (Diameter of Fiber) | Weight (g/㎡) | Thickness (μm) | Tensile Stress (N/1.5cm) | Tensile Elongation (%) | Air permeability (cc/c㎡/sec) |

||

| MD | CD | MD | CD | ||||

| Regular | 9 | 44 | 9 | 4 | 3 | 5 | 374 |

| 14 | 59 | 16 | 8 | 2 | 4 | 198 | |

| 40 | 100 | 74 | 39 | 3 | 4 | 40 | |

| Fine | 4 | 16 | 11 | 5 | 3 | 7 | 204 |

| 6 | 18 | 22 | 10 | 2 | 3 | 113 | |

(Tested by KURARAY CO., LTD. )